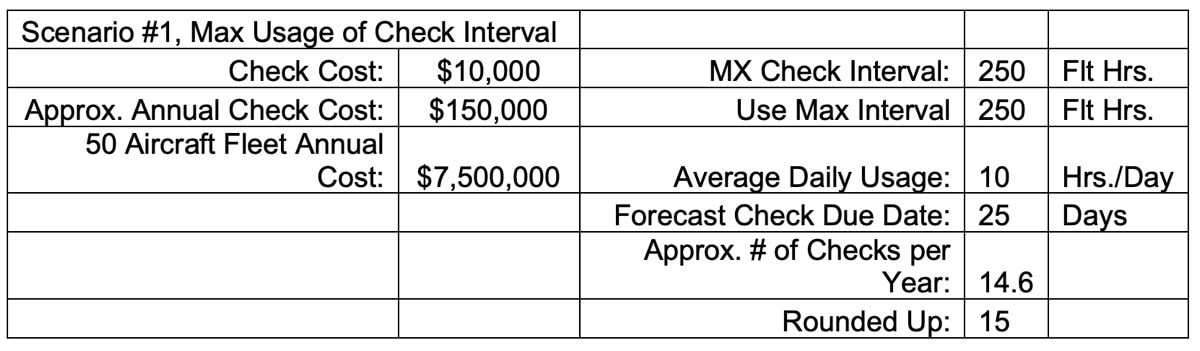

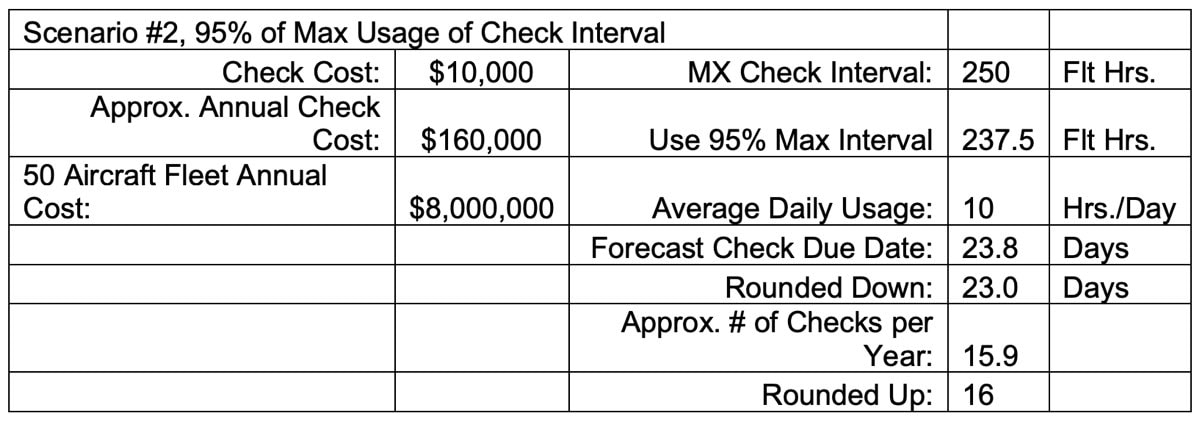

Maintenance and Engineering Effects on Daily Operational DisruptionsIn an ideal airline world, all departments that manage or affect daily flight operations would work closely together in perfect harmony to execute the flight schedule without a hitch. Within this beautiful and harmonious operational bubble, sometimes called an Integrated Operations Control Center (IOCC) or Integrated System Operations Center (ISOC), the airline would flawlessly execute its flight schedule without any hiccups or disruptions. Unfortunately, this utopian world where everything goes as expected does not exist, and operational disruptions do occur regularly. Disruptions that can occur include but are not limited to: severe weather conditions, Air Traffic Control (ATC) situations, ground management operations, passenger service problems, and maintenance issues. Those who have lived in this environment know hiccups and operational disruptions will occur even on a good day. Being prepared at the beginning of the operating day and preparing for things to go wrong is everyone's responsibility. Being prepared means being ready to make hard decisions and watch for opportunities to reduce or eliminate the number of disruptions and minimize the operation's impacts. Departmental policies that are well written and thought out, effective decision-making processes and procedures, and sophisticated tools and software all play vital roles every day at every airline. Most airline industry experts broadly consider flight, ground, and maintenance and engineering (M & E) operations as having the most direct effect on operational outcomes. Other factors such as airport authority operations, air traffic control situations, and weather also contribute, but the airline has no control over these operational disruptions. The relationship between maintenance operations and flight operations has always been a symbiotic one. The fact is that without one, the other has no purpose or function. Maintenance has no reason if the airline doesn't have a flight schedule and needs aircraft to fly that schedule. Flight operations have no role if maintenance doesn't maintain and provide serviceable aircraft to fly the schedule. This relationship can quite literally make or break an airline. Through a series of white papers, we would like to share some general background information on several aspects of disrupted operations. These white papers will outline personal experiences in each of these areas and attempt to highlight where process improvement, the introduction of technologies, or a combination of the two improve daily operational outcomes. Through continuous process improvement programs and the implementation of advanced technologies and software, M & E can significantly reduce its effect on daily operational disruptions. Ongoing process improvement activities and introducing technologies have proven to be reliable methods of improving efficiency and reducing disruptions. Conducting improvement workshops with all individuals directly associated with a process allows each person to see how their work and job responsibilities can directly affect the operation. First and foremost, the M & E department's primary goal is to ensure that a safe, compliant, and serviceable aircraft is available to meet the flight schedule requirements. This particular white paper installment will focus on managing scheduled and unscheduled maintenance events, and maintenance planning can directly affect daily flight operations. Scheduled and Unscheduled MaintenanceM & E's most essential responsibilities are the management of scheduled and unscheduled maintenance events. M & E is specifically responsible to the airline to conduct all scheduled and unscheduled maintenance as prescribed in the approved maintenance program and the airline processes and procedures manual. By doing so, serviceable aircraft will be available to the airline to meet the flight schedule. During the execution of daily flight operations, M & E departments are held accountable for operational disruptions in several ways. The most often identified (chargeable) M & E disruptions are generally non-deferrable aircraft system malfunctions requiring extensive maintenance and leaving an aircraft on the ground and out of service for extended periods. Flight schedule disruptions may also result from detailed troubleshooting of aircraft inflight reported faults or pilot reports (PIREP) or the lack of available parts to fix a reported fault. Applying a Minimum Equipment List (MEL) deferral to an aircraft, conducting associated maintenance actions resulting from MEL application, and evaluating structural damage are other examples of an aircraft being out of service or returned to service late. Let us first look at an example where conducting a process analysis might improve M & E's potential effect on flight operations. In this example, the appropriate ground support equipment is not available or correctly staged to accomplish an aircraft thru-flight. In this case, ground support or maintenance personnel would not be capable of performing required thru-flight tasks. A flight schedule disruption will likely occur. The airline will charge either maintenance or ground operations with the schedule disruption. In this situation, an example of process improvement and procedure alteration would be to evaluate where ground support equipment is being staged in preparation for thru-flight activities. Stagging ground support equipment seems on the surface to be an obvious area where most airlines would have already made efforts to improve, but this is not always the case. Evaluations have shown that proper stagging of equipment on a particular side of the aircraft in a specific order as needed to accomplish tasks has significantly improved thru-flight turnaround efficiencies. Disruptions can be reduced or eliminated. As previously mentioned, accomplishing necessary maintenance activities during flight operation periods can significantly contribute to flight schedule disruptions. Technologies that provide advanced awareness of onboard aircraft problems have allowed mechanics to address the faults immediately. Using wireless laptops with advanced software applications that provide immediate access to company servers enables maintenance personnel to conduct preliminary troubleshooting, parts research, parts ordering, and repair actions at the aircraft without returning to an office area for access to computer terminals. Additionally, all stakeholders have immediate access to information and status regarding the fleet through advanced communications systems. The use of advanced tools and software can significantly improve the efficiencies of M & E; however, the implementation of these tools can present significant challenges. First, defining the actual business requirements or identifying the specific operational challenge that a potential technology must address is often the main challenge. Identifying these requirements often comes from detailed process mapping. During the mapping exercise, having clear ideas of these processes and expected outcomes is very important. It can become very frustrating for the end-users to put tools in place that do not accomplish the job requirements, don't meet the intended operational improvement, or don't show the efficiencies intended. Maintenance PlanningMaintenance Planning is considered a "Back-office" department divided into line maintenance and base/hangar maintenance functions. Daily Checks, "A" Checks, and deferred maintenance are considered line maintenance: heavy maintenance, "C" and "D" Checks, and significant modifications are considered base/hangar maintenance. Both are categorized as scheduled maintenance. Whether line or base, planning activities are often perceived as not directly affecting the outcome of daily flight operations. However, if not adequately managed, scheduled maintenance can directly affect the daily flight schedule's outcome. Modern, sophisticated software tools allow a maintenance planner to have visibility to all of the necessary maintenance details about every aircraft in the fleet. The software provides visibility to available downtime, required resources, and resource availability. By integrating with all other operational department software applications, the planning system collects aircraft usage data and maintenance task completion data. It then presents a forecast for when maintenance tasks are required to be accomplished again. The planning department is responsible to effectively plan so scheduled maintenance events will be completed within the approved maintenance program and will not disrupt the daily flight schedule. Also, they have a responsibility to manage maintenance costs. The most effective way to control cost is by awareness of usage and control of maintenance intervals. In other words, take advantage of the software's ability to provide visibility to all of the hours, cycles, or day intervals of aircraft tasks, but stay compliant with the program. Let's review a couple of scenarios. For both examples, the planners want to get the most out of each maintenance interval. In the first, operational consequences are not considered. It is purely an economic scenario. Let's assume all scheduled maintenance tasks will have an assigned fixed maintenance cost. In the first scenario, an A-Check has a fixed cost of $10K and has a 250-hour interval. The following matrix depicts a 50 aircraft fleet, flying 10 hours per day and accomplishing the A-Check at exactly the specified 250-hour interval. As the matrix shows, a single aircraft would have an A-Check due every 25 days and require approximately 15 checks a year. A-Check Maintenance for one aircraft would equate to $150,000 per year, and a fleet of 50 aircraft would be $7,500,00 per year. The drawback in this scenario is that if planned on exactly the 25th day, the aircraft would be considered Aircraft-On-Ground (AOG) and not be allowed to dispatch again until the check is accomplished. This planning method is not ideal because it is severely restrictive to the Flight Operations department and limits their flexibility with the flight schedule. Compromise in the planning methodology is a must to solve this operational dilemma. Maintenance and flight operations groups must agree to a tolerance level for maintenance accomplishment and flight schedule available. In this second example, let's assume flight operations and maintenance operations agreed that a 95% usage rate, or maintenance yield, on maintenance tasks is tolerable. At the same task interval of 250 hours, the check would now come due at approximately 237 flight hours. In this scenario, flight operations can maintain the flight schedule, and maintenance operations can effectively manage the maintenance activities. Unfortunately, this flexibility comes at $10,000 per year in added maintenance costs per aircraft or approximately $500,000 on a 50 aircraft fleet.

Maintenance must make aircraft available to meet all scheduled flight requirements, and at the same time, be efficient in maintenance planning, execution, and cost control. In today's environment, specifically developed tools and software assist in building and executing maintenance plans. When properly used, these tools will provide accurate maintenance forecasts, provide visibility of immediate maintenance requirements, and ensure compliance with the maintenance program. Additionally, as described in the scenario above, more efficient cost management can be achieved with established usage goals. The operational and maintenance related data for an aircraft can be collected and analyzed from its first day in service. The reliability, maintenance programs, engineering departments, and maintenance planning use this information to affect maintenance program changes and keep the maintenance plan current. All departments will produce reports and recommendations intended to enhance maintenance program compliance further and lead to economic efficiencies and cost reductions. These reports are concentrated on maintenance disruptions, part removal data (both planned and unplanned), planned maintenance task usage, and unscheduled maintenance findings. Collection of this information can often mean accessing multiple information sources. To conclude this white paper installment, it is essential to note that continuous process improvement and ongoing upgrades to tools and technology in maintenance management and maintenance planning will undoubtedly positively affect daily airline operations. Cooperation, collaboration, and communication are essential elements for the airline's goal regarding operational disruptions. Stay tuned for more white paper installments discussing other vital aspects of flight and maintenance operations. Comments are closed.

|

envision aviation advisorsSharing insights from our more than 100 years of combined experience in the aviation industry across 6 continents Archives

October 2021

Categories |

envision aviation advisorsSeattle, WA, USA

|

Shortcuts |

|

|

Copyright © 2024 · Envision Aviation Advisors, Seattle, Washington USA

|

Site built and marketed by Blockbeta Marketing

|

RSS Feed

RSS Feed